Your parts matter to us! Bright or satin finish; black, clear, or colored; just a few parts, or a whole bunch; from tiny parts to large (up to 6 feet), we look forward to serving you!

How it works: unlike electro-deposited metallic plating, where plating builds up by depositing on a base metal, an anodic coating penetrates and then grows on the base metal by converting aluminum to aluminum oxide. The ratio of growth/penetration for anodic coatings is typically 50/50. During sulfuric anodizing, aluminum is the only metal involved.

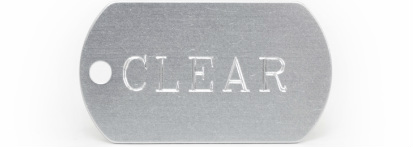

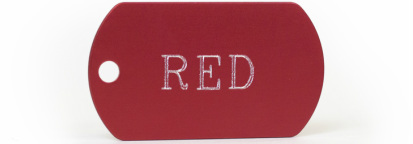

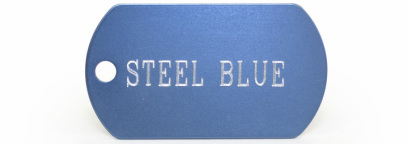

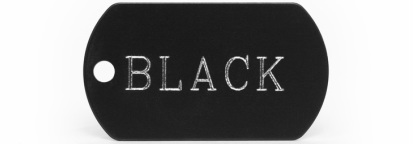

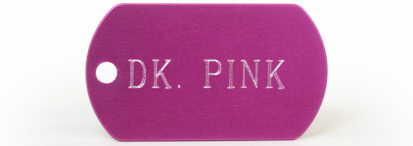

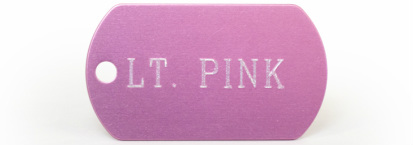

Proper formation of aluminum oxide coatings (AKA aluminum anodizing), creates a natural decorative appearance as well as an increased resistance to corrosion and abrasion. These are just a few of the benefits associated with aluminum anodizing. Normally between .0001″ to .001″; thick, sulfuric anodizing lends itself readily to clear anodizing and color anodizing work, as the coating is more transparent than other types of anodizing. In addition, it serves as a base for color absorption to create decorative finishes. Dyes can be deposited into the pores of the anodized layer and then sealed. The result is a highly desirable, rich, intense, permanent color anodizing finish.

How it works: unlike electro-deposited metallic plating, where plating builds up by depositing on a base metal, an anodic coating penetrates and then grows on the base metal by converting aluminum to aluminum oxide. The ratio of growth/penetration for anodic coatings is typically 50/50. During sulfuric anodizing, aluminum is the only metal involved.

Proper formation of aluminum oxide coatings (AKA aluminum anodizing), creates a natural decorative appearance as well as an increased resistance to corrosion and abrasion. These are just a few of the benefits associated with aluminum anodizing. Normally between .0001″ to .001″; thick, sulfuric anodizing lends itself readily to clear anodizing and color anodizing work, as the coating is more transparent than other types of anodizing. In addition, it serves as a base for color absorption to create decorative finishes. Dyes can be deposited into the pores of the anodized layer and then sealed. The result is a highly desirable, rich, intense, permanent color anodizing finish.